ENGINES

In 1948, The Ford Motor Company introduced the F-Series with the F-1 through F-6 light and heavy duty trucks. Depending on the series, Ford offered four different engine options ranging from a 95hp Straight-6 to a 145hp Flathead V-8. A year after Ford launched the F-Series truck, Jarvis began operations producing the taps used by the engine manufacturers of the time.

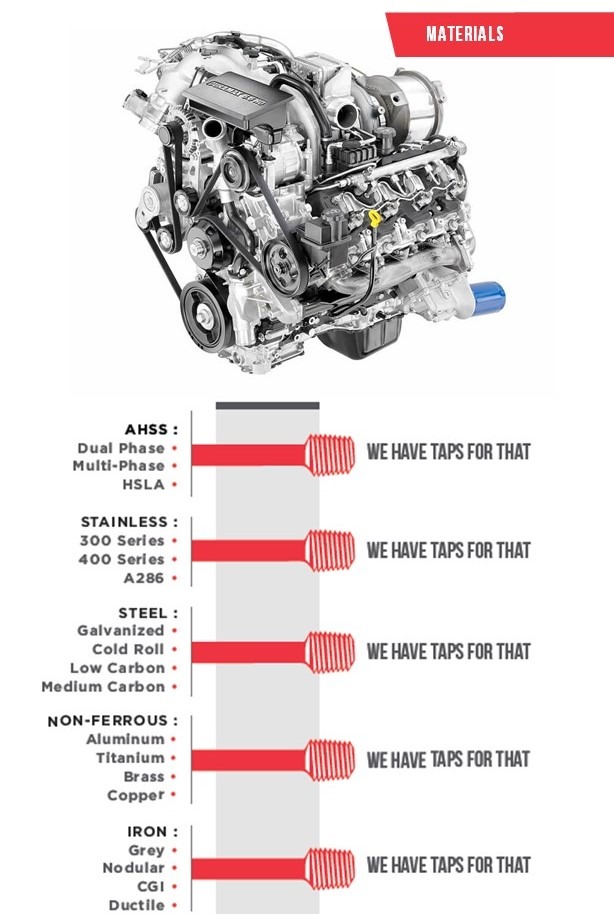

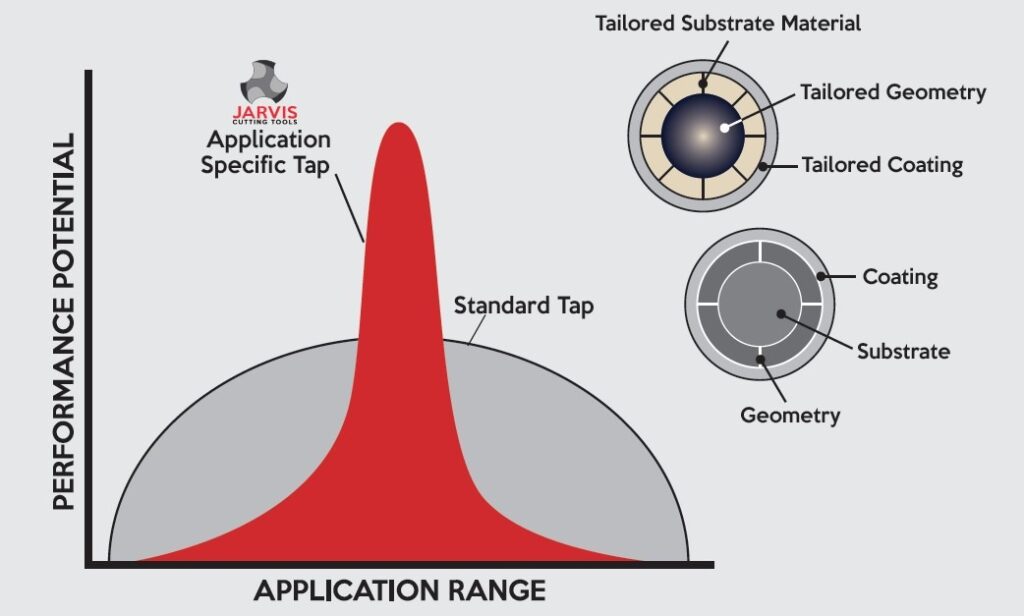

The high output, efficient gas and diesel engines of today require close tolerance manufacturing of light weight, high strength materials. Jarvis works closely with engine manufactures around the world designing and producing application specific taps used in high volume transfer lines and CNC milling centers.

ENGINE COMPONENT MATERIALS JARVIS IS TAPPING:

- Aluminum

- Aluminum Die Cast

- Cam Shaft

- Carburetors (small engine)

- Compacted Graphite Iron

- Connecting Rod

- Crank Shaft

- Cylinder Heads

- Ductile Iron

- Engine Blocks

- Fly Wheel and Cover

- Gray Cast Iron

- Main Bearing Cap

- Spark Plug Holes

- Steel Forgings

- Titanium 6AL4V

- Valve Guides

- Water Pump

Engine manufacturing is all about cycle time and quality and Jarvis application specific taps offer clients significant improvement on both those metrics

NEED A SPECIAL TAP FOR AN ENGINE APPLICATION?

FILL OUT A SPECIAL TOOL REQUEST FORM HERE

DIESEL ENGINE / J80 TAP CATALOG

VIEW OUR CURRENT SELECTION OF TAPS FOR DIESEL ENGINE APPLICATIONS

JARVIS OFFERS SELECT APPLICATION SPECIFIC TAPS (STANDARDS) OFF-THE-SHELF