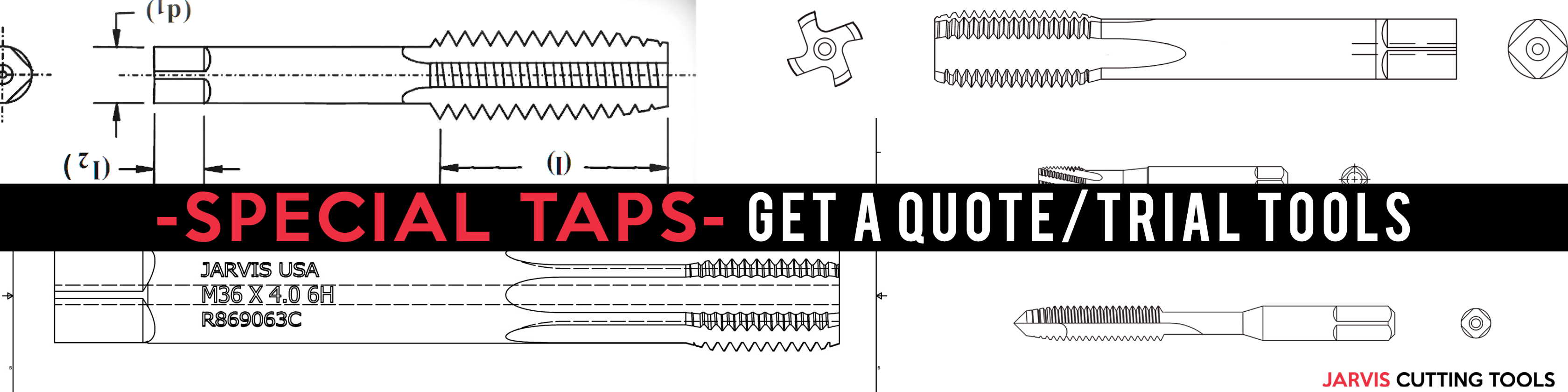

Jarvis makes a variety of specials to satisfy and exceed customer expectations.

We can design and manufacture special tools to your exact print specifications.

Here are some of the Special Tap Features Jarvis offers:

- Special tap dimensions including DIN, JIS, ISO, and custom

- Special Pitch and Pitch Diameters

- Multiple Leads for both Cutting and Roll Forming

- Special thread forms including: ACME, Buttress, British Association, Ball, Jarlock (Locking Thread form), and Special Radii and Flank Angles

- Special Tapers

- Coolant Hole Thru and Radial

- Bent Shank Taps for High Speed Nut Tappers and Screw Machines

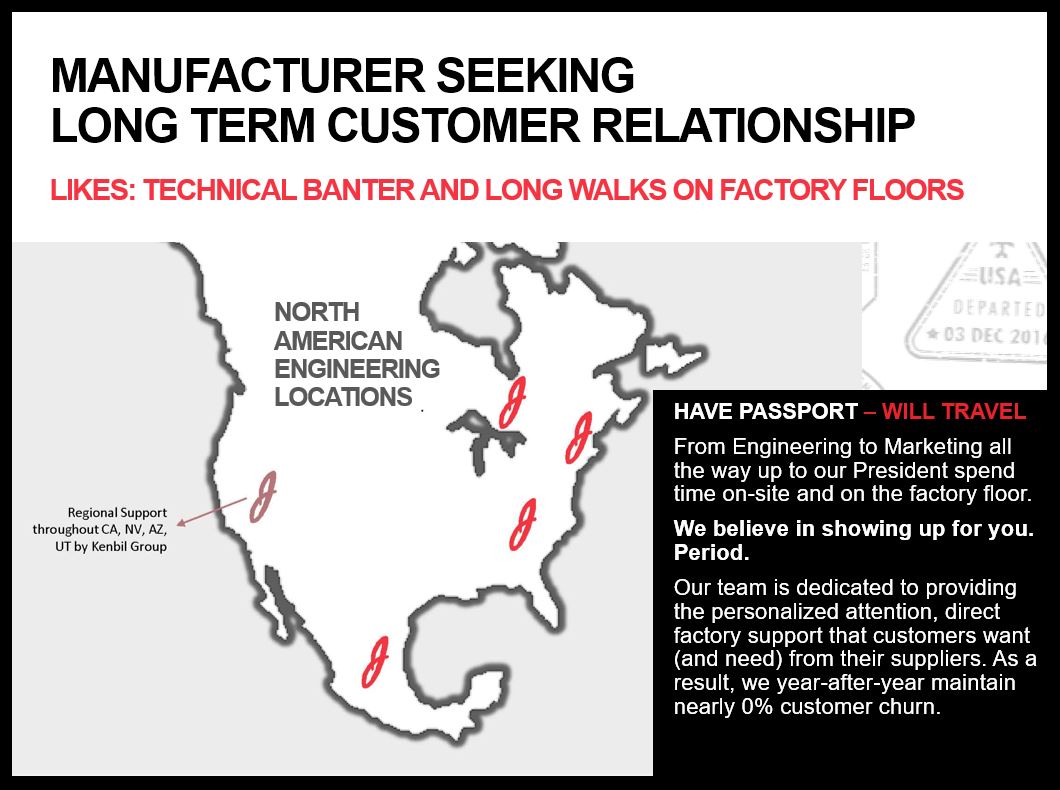

Beyond the physical attributes of the tap itself our Special Tools are backed by our on-site technical, engineering and sales support.

SPECIAL TAP SERVICE & TECHNICAL SUPPORT

STOPPING BY ≠ VALUE

Suppliers who just “stop by” waste time and do not provide value.

Customers need suppliers to provide a “value add” relationship.

I want to describe how Jarvis provides on-going support to our special tap customers:

We believe in being available. Period. Our team is dedicated to providing the personalized attention and direct factory support that you need. From the President, to Engineering, to Marketing and to Sales, we are available – either in-person or on the phone. Sometime we need to discuss things in a “planned” way. These are regular visits based on your needs and the opportunities.

• Proposed new cost savings

• Review supply chain status

• Understand current and future needs, challenges, and projections

Example 1 -

Onsite Visit to an Aerospace Fastener Customer

- The implementation of new designs that have been tested. This is understanding current open orders, how we can adjust, and talk about usage.

- (1) Testing new designs in other applications.

- (2) Worked with engineering, production, and quality to watch testing and develop consensus on results.

- (3) Discuss ordering patterns and inventory for improved delivery performance. They want to work on a Made-to-Order basis and we needed to discuss their ordering patterns and their inventory levels to handle unexpected demand.

- (4) Sometimes things don’t go as we want any you have an immediate need. These can be:

- • Supply chain issues

- • Performance issues

- • New projects

Example 2

Addressing Issues at an Automotive Fastener Company

- The customer had unexpected demand. They had gone from one machine (with 4 spindles) to 3 machines and were using up their inventory of taps. They called me on my cell phone with their urgent demand. I was at an airport lounge and was able to schedule a three-way conference between the customer, myself, and production. We understood clearly their needs – specific counts and specific dates – and were able to adjust that evenings production to move their next order through production to keep their production up.

- The same customer called to report a drop in tool life. Suddenly the taps were achieving 30% less tool life and they needed help. We flew the next day to the account and tracked output on their machines. We found that one of the four spindles was out of alignment and causing broken taps.