AUTOMOTIVE

In 1947, Albert H. Tinnerman hoisted a 3300 pound Plymouth off the ground supported solely by one Tinnerman Speed Nut. This daring task was to prove to the auto makers of the time that threaded fasteners were just as robust as welding or riveting for holding fenders and body panels to an automobile frame. Ford was one of the first auto manufacturers to utilize these new fasteners using them in nearly 400 different applications.

Two years after Tinnerman’s bold demonstration, Jarvis began manufacturing the taps Tinnerman required to produce the Speed Nut. This long tradition of working closely with world-class fastener producers continues today.

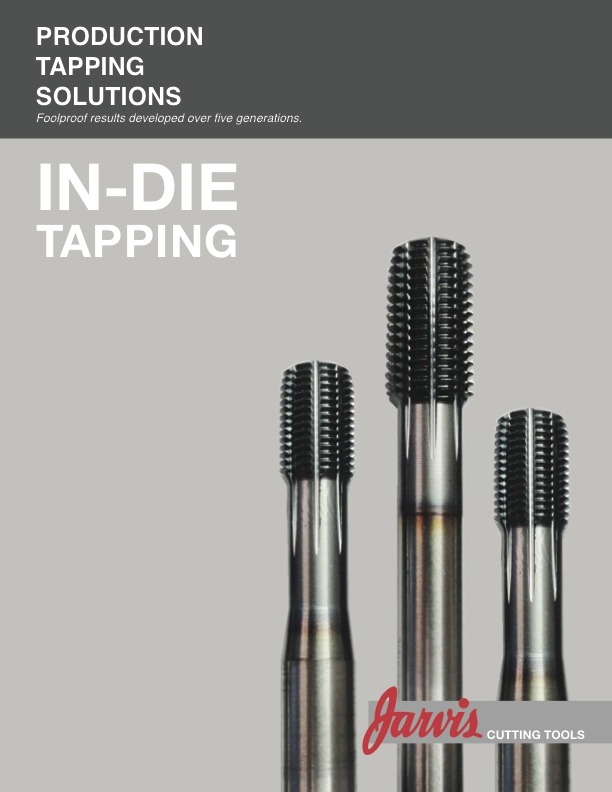

Jarvis designs and manufactures application specific taps for all methods of fastener production including bent shanks for high speed nut tappers, secondary tapping on vertical & inclined tappers, in-die tapping units and screw machine applications – View Our Machine Builder Partnerships

AUTOMOTIVE AND INDUSTRIAL FASTENER MATERIAL JARVIS IS TAPPING:

- Aluminum

- Alloy Steel

- Barrel Nuts

- Brass

- Cage Nuts

- Clinch Nuts

- Hex Nuts

- Lock Nuts

- Low and High Carbon Steel

- Pierce Nuts

- Screw Thread Inserts

- Spindle Nuts

- Spring Steel

- 304 & 316 Stainless Steel

- Tee Nuts

- U-Nuts

- Weld Nuts

- Wheel Nuts.

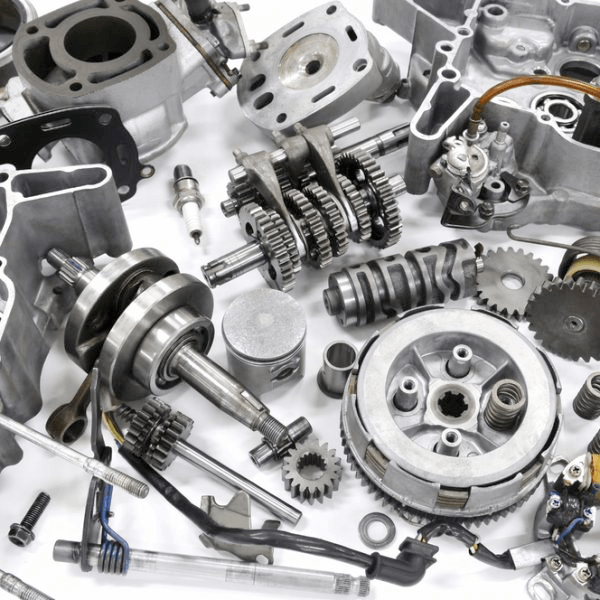

In 1916, William C. Durant, founder of General Motors, formed United Motors Corporations as a manufacturer of automotive components and accessories. In 1944, United Motor Service became a fully integrated division of GM later to be known as AC-Delco.

Five years later, Jarvis launched operations producing high speed steel tap supplying tools to the metal cutting industry including automotive component manufacturers. Jarvis understands the fast moving world of automotive and truck component manufacturing and the need for innovative tap designs that maximize tool life and provide superior thread finish.

Jarvis engineers application specific roll form and cut taps to exceed the demanding requirements of automotive and truck component manufactures throughout North America, Mexico, Europe, and South East Asia.

AUTOMOTIVE AND TRUCK COMPONENT MATERIALS JARVIS IS TAPPING:

- Axle Shafts

- Brake Pins

- Cast Aluminum

- Cast Iron

- Cam Shafts

- Connecting Rods

- Crank Shafts

- Differential Cases

- Ductile Iron

- Engine Applications

- Hub and Bearing Assemblies

- Low and High Carbon Steels

- Nodular Iron

- Ring Gears

- Steel Alloys

- Steering Knuckles

- Tie Rod Ends

- Transmission Housings

- Transmission Valves

- 1060 & 1080 Steel Forgings

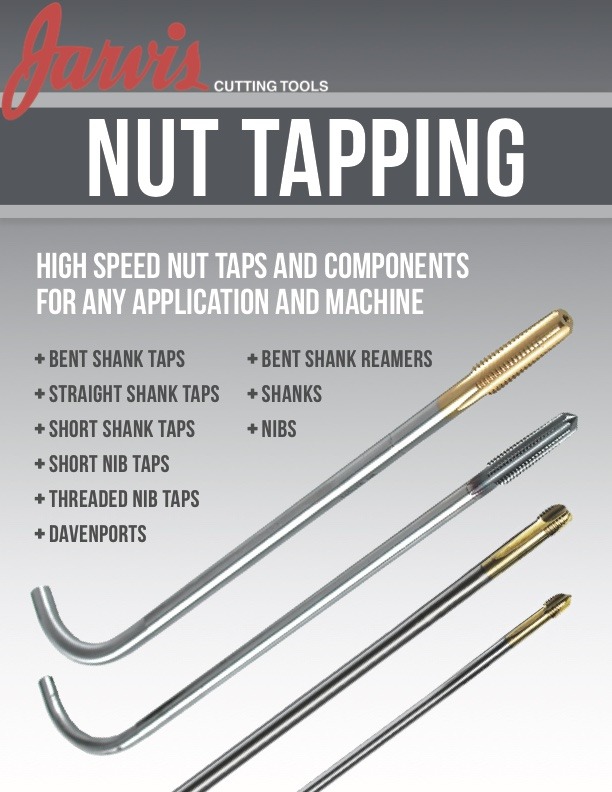

FEATURED APPLICATION: NUT TAPPING

Jarvis high speed nut taps (and components) for any application and machine:

– Bent Shank Taps (for tapping small fasteners on automatic tapping machines high speed nut tappers or bent shank attachment)

– Bent Shank Assemblies (for tapping large fasteners in high speed nut tappers)

- Straight Shank Taps

- Short Shank Taps

- Threaded Nib Taps

- Short Nib Taps

- Couplings

- Shanks

- Nibs

Threaded shank, 6 flutes, 18 thread lead, premium steel

This tool is used to make fasteners (Nuts). Specifically, the 7/8-9 AH tap is tapping industrial steel hex nuts at a rate of 10,000/hour. It is held tight to a thread shank by a coupler and floats in a tapping machine.

This tool only spins in one direction and the fasteners load up on the shank and fall off the end as another fastener is tapped on to it.

The reason for the tap, coupler and shank is so the person using the tap only needs to replace the tap when it is worn out rather the entire assembly

On smaller sizes this assembly is one piece and labeled as a bent shank tap.